We Stock PSS Seals in Cairns

The Most Popular Seal Around

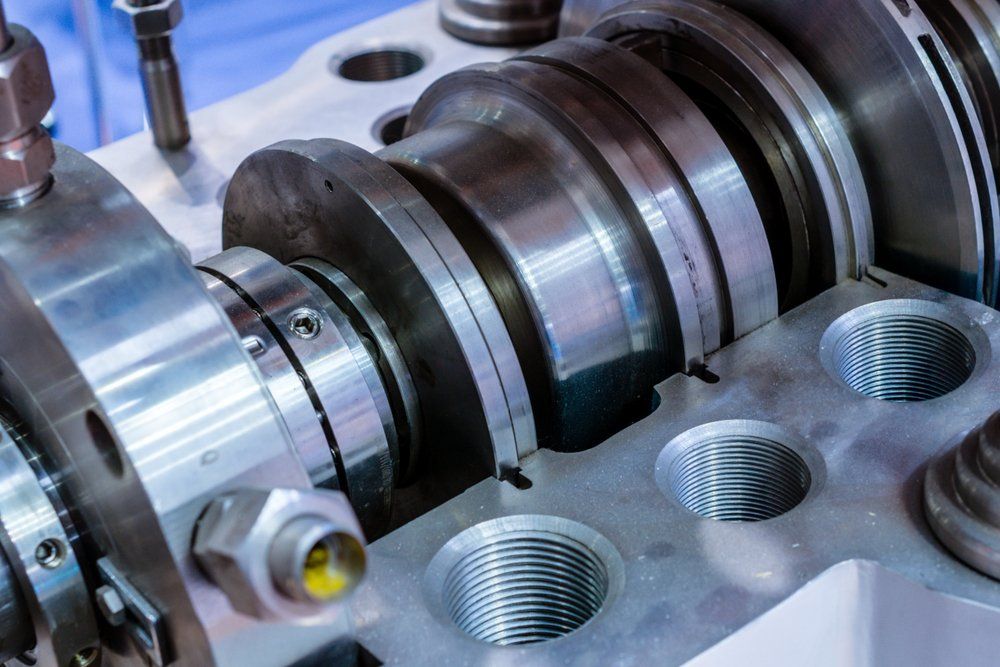

Want quality marine parts at a competitive price? You can’t go past the PSS Shaft Seal—the leading dripless seal on the market. KG Mechanical Services in Cairns is proud to be an authorised dealer for this product. PSS seals keep your vessel's engine and propulsion system dry and clean, so it’s protected from the corrosive effects of salt water. The unique seal design eliminates the need for a packing gland, making them much easier to install and maintain than traditional packing glands.

PSS Shaft Seals are available in a variety of sizes and configurations to fit your specific application and our trained technicians can help you select the right seal for your vessel. So, if you’re looking for a shaft seal that will provide years of trouble-free operation, give us a call at KG Mechanical Services. We'll be happy to answer any questions you have. Why not also ask about our

new pumps on offer? Call on

(07) 4092 6627.

Watertight to Reduce Maintenance

Here at KG Mechanical Services, we have more than four decades of experience in working with marine parts and only supply products that our valued customers can rely on—the PSS Shaft Seal is one of those.

Because it’s 100% watertight it helps to reduce water in the bilge, as well as wear to the propellor shaft. This means it will greatly reduce your need for maintenance and other costs. Not only are they popular with the most reputable boat builders, but PSS Seals are recognised as the best aftermarket seal worldwide. To find out more about how this incredible seal works, call our experienced team today.